Oil used as insulating agent in transformer has great importance. Any contamination in the oil like foreign particle, small or large oil, can affect the functioning of transformer at great level. So it very important to purify the insulting oil before filling it into the transformer. Rajasthan Powergen, the best transformer manufacturing company in India is sharing different options trending in transformer manufacturing companies to purify the oil.

Transformer oil purification plant also known as oil filtering system or purifier is used to purify insulating oil which is used in transformer. To boost the quality of transformer oil, transformer manufacturing company must eliminate gas, moisture or any solid content from it. For better results, most manufacturers are purifying oil with different kinds of oil filter machines or oil treatment equipments.

Besides Vacuum oil purifiers, other method manufacturer use to remove gas and water content from oil is through oil heating degassing vacuum dehydration process. In this method, transformer oil is heated using oil mist spray and as a result of which gas and water content in the oil get vaporized. Water container is used to expel excess water which was cooled down by the condenser. To prevent ageing of transformer oil, the temperature of oil is generally kept low around 60 degree. This approach for degasification and dehydration works far better than those of conventional methods.

If transformer oil is highly contaminated or dirty, because of the amalgamation of molecule of oil with smaller impurities, manufacturer uses specialized waste oil processing system. In this system, activated alumina or silica is used as adsorbent. Silica gel tank set up is partitioned into various chambers so that there is complete access to silicone and transformer oil. To accomplish full absorption effect, the process of heating of transformer oil in gel tank is repeated. After the complete absorption of contaminants, the oil is transferred into the filtration tank.

It is very important to monitor and check the absorption effect during the regeneration of oil. Waste oil containers or cans should be properly cleaned and dried before utilizing it again.

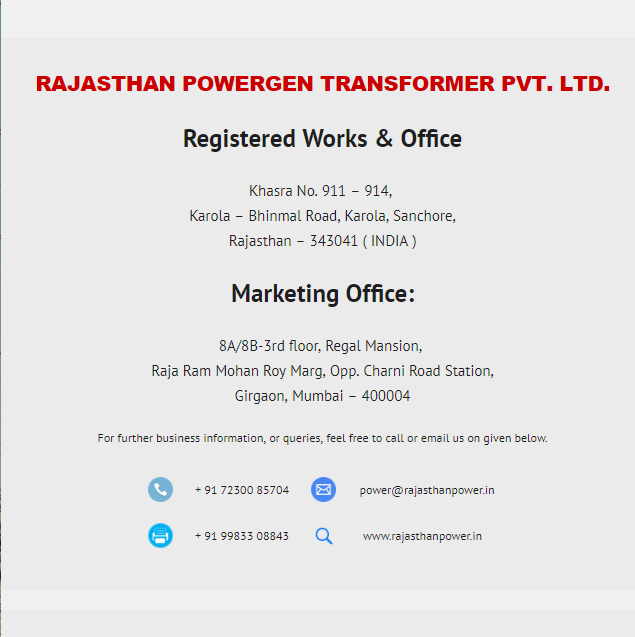

These are the basic methods which transformer manufacturer uses to make insulating oil or transformer oil contaminant free. Rajasthan Powergen Transformer P. Ltd., best transformer manufacturing company in India uses above techniques of purifying insulating and transformer oil, so that the transformer manufactured by them works smoothly.