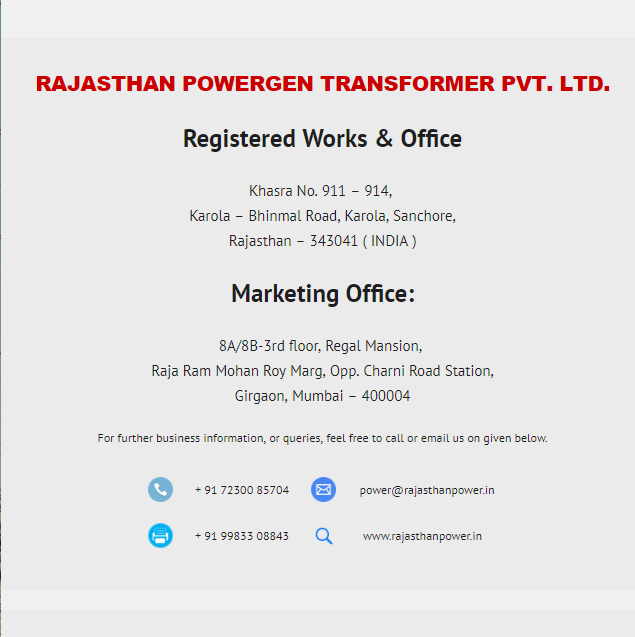

Want to get information regarding the basics and working of transformers? The leading distribution transformer manufacturer in India, Rajasthan Poweregen, is explaining the basics of transformer operation to help customers get more information.

During No load why the power factor of the transformer is very low ?

There are two types of Current that flow through the transformer. First one is the Magnetizing current (Im) which is perpendicular (900) to the applied voltage and the second one is the phase current which is in phase to the applied voltage. Times, when the load on the transformer is less most of the excitation current drawn by the transformer from the primary winding, is to magnetize the path. Thus the excitation current which is drawn by the transformer during no-load condition mostly consists of a magnetizing component of current which is used to provide a magnetic field in transformer circuits.

What happen when Transformer is given DC supply ?

Primary winding no back emf is generated when DC supply is provided to the transformer. The Back limits the current which is drawn by the machine thus making it highly important. If there is no back elf the transformer will draw huge currents which results in burning down of primary winding.

At what power maximum efficiency of power transformer and distribution transformer is designed Maximum efficiency of the transformer is reached at certain load factor (α) when core losses of transformer is equal to the copper losses.

PCore loss = α2 X PCopper loss

From the above equation for particular load factor (α) maximum efficiency of a transformer is designed when core loss is equal to copper loss. For a transformer core losses remain same irrespective of the load and copper losses varies based on the loading. For a transformer maximum efficiency is designed for particular load factor when core and copper losses are same.

Core loss for a transformer is designed based on the application of transformer so that both core losses and copper losses will be same.

For power transformer delivering bulk power employed in generating stations and other substations power it deliver will not vary round the clock and delivers full load. Hence power transformers are designed to have maximum power at full load. Whereas power deliver capacity of distribution transformers which deliver power vary with time duration of the day. Hence distribution transformers are designed to have maximum efficiency at 50% of the rated full load

What are the conditions for parallel operation of two transformers ?

For parallel operation of the the following conditions have to be met-

• Polarities of both the transformers being used should be same otherwise it can lead to short circuit. The Voltage rating of the both primary and secondary of the two transformers operating in parallel should be same. Per unit impedance, phase displacement, phase sequence of the transformers should be same.

Why Silica gel is used in transformers?

Silica Gel is used to remove the moisture in the air entering in to the transformer. Their colour changes from blue to pink after absorbing the moisture. During the breathing of the transformer air enters in to the transformer.

Leading distribution transformer manufacturer in India, Rajasthan Powergen takes care of all these basic things while designing transformers and offers widest range of best quality transformers so that the customers can get the desired product easily.